Powerful planning, even for rush orders

Nothing is as dynamic as the production planning in a printing company. Last-minute orders, changes made just before the start: how do you keep track of the material stock and prevent unforeseen shortages? With the material requirement planning function in MultiPress, of course!

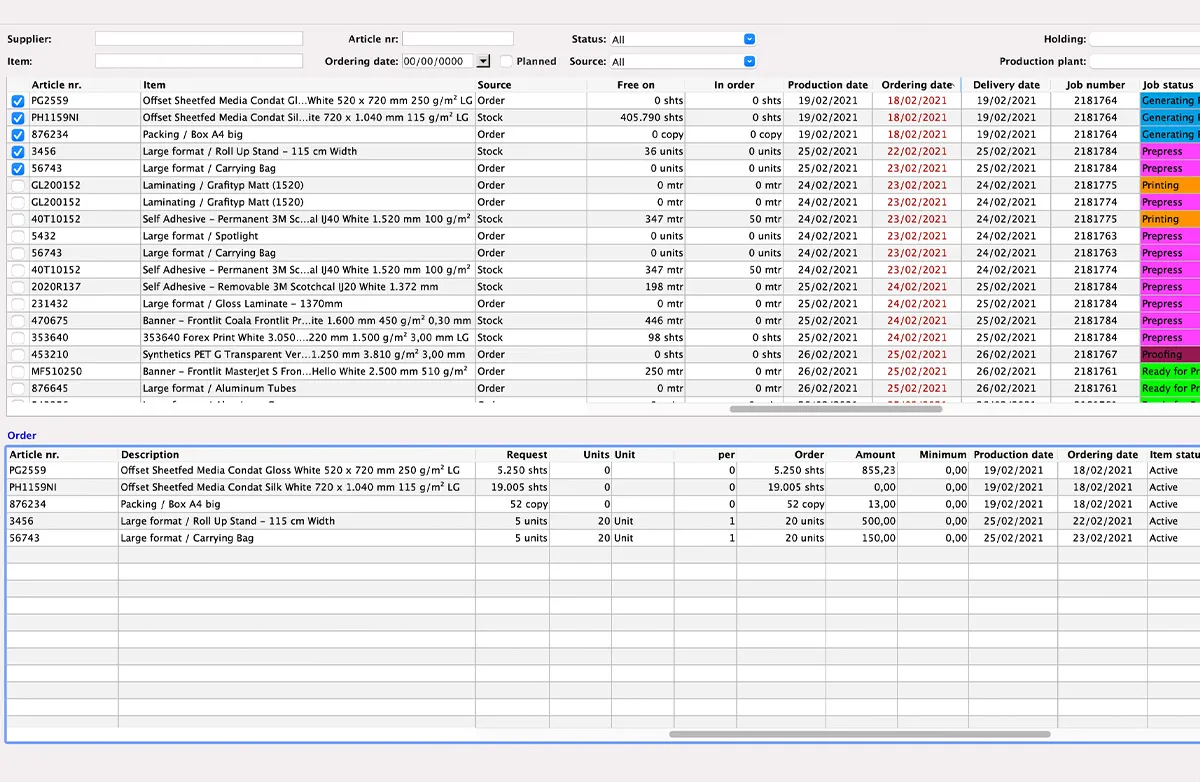

The centralised material requirement planning in MultiPress contains a unique algorithm that determines which raw materials should be ordered or reserved and when. In logically ordered phases, the availability of components, materials and products is monitored in order to automatically create production orders.

All production planning is subject to changes that can considerably disrupt the planning. Changes in the print run or the paper type as well as rush orders that require immediate production can seriously disrupt the daily plan. Especially if, for example, it turns out unexpectedly that not enough paper has been reserved. However, this costly production standstill is easy to avoid!

The material requirement planning function in MultiPress enables you to manage your orders and material reservations centrally. This gives you a clear overview which you can check for additions or reductions. In this way, materials can even be changed on the fly without affecting stock management. The smart algorithm in the MRP module determines which materials must be ordered or reserved and at what time.

- Efficient and secure: with the material requirement planning module in MultiPress you can always be sure that there is enough material in stock

- Save time and costs: MultiPress identifies possible material shortages at an early stage and so prevents production downtimes and disruption to planning